1. Description

EMHB-1600 honeycomb paperboard machine is to expand and laminate honeycomb paper to get paper panel.

2. Paramters

| Max. paper panel width | 1600mm |

| Max. mechanical speed | 15m/min |

| Honeycomb paper board thickness range | 6-100mm |

| Min. cutting length | 500mm |

| Cutting tolerance | ±5mm |

| Production line dimensions(L*W*H) | 42000mm*3800mm*2300mm |

| Total power | 170KW |

3. Features

-

Heavy frame and steady design

-

PLC system for control, adopt HMI for operation.

-

New design with space-saving function, can fit to most customers demand.

-

High efficient gluing system, only need 10 minutes to change the gluing roller.

-

New design for the edge trimming.

-

High frequency for cutting, Max. 800times/min.

-

The cutter is long life cycle, around 15 days to sharpen it.

4. Equipped Machines

-

Paper stand

-

1 set hydraulic shaft less paper stand.

-

Max. paper roll width 1600mm.

-

Core feeding unit

-

Screw adjustment for core guiding.

-

Roller pressing for core expander.

-

Chain driving system

-

Core drying and stretching unit

-

Infrared heating for glue.

-

Rollers conveying for core stretching.

-

Chain driving system.

-

Length: 6000mm

-

Glue unit

-

Roller coating for gluing.

-

Electrical control system for glue consumption.

-

Paper tracker system for both layer.

-

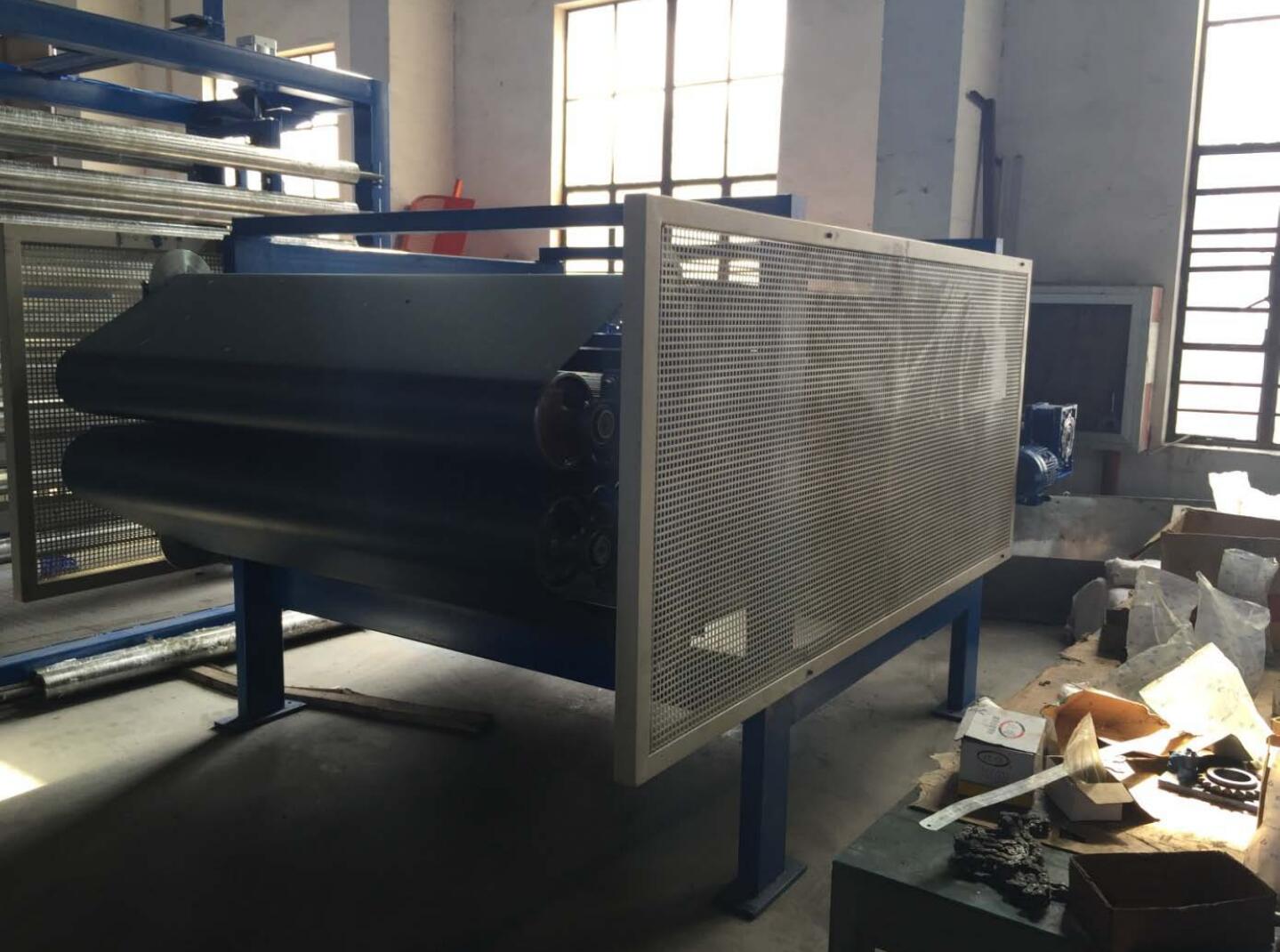

Belt Pressing unit

-

PVC belt with hole.

-

Length of the pressing section 2150mm.

-

Screw rod drive lifting system.

-

Heating unit

-

Length of deck: 3000mm

-

Total power: 78KW

-

Cooling unit

-

Total length: 6000mm

-

Total power : 3KW

-

Slitter

-

Max. width of honeycomb sheet before slitting 1600mm

-

Total quantity of slitting blade: 3

-

Honeycomb panel thickness range: 6-100mm

-

Single saw cutter

-

Cut off precision: ±5mm

-

Total power:9KW

-

Total weight: 3000kg

-

Conveyor

-

Length: 2000mm

-

Power: 1.5KW