Description

As the essential part for dry end in the corrugated board production line, it applies complete computer control system to realize fast changeover, high precision scoring and high quality slitting, thus reduces downtime and improves productivity significantly.

Features

Imported high quality industry computer and PLC compose the machine NC system

High quality linear guides and high-precision ball screw guarantee a≤±0.5mm slitting and scoring precision.

Momory can store 999 orders, auto order change or manual order changing without stopping.

Automatic synchoronizing with the corrugated production line speed, can be connected with production mangement system with excellent compatibility.

Quick order change within 3-6 seconds(Servo type: 3 seconds). Two sets runing simultaneously can realize fast order change, less waste paperboard.

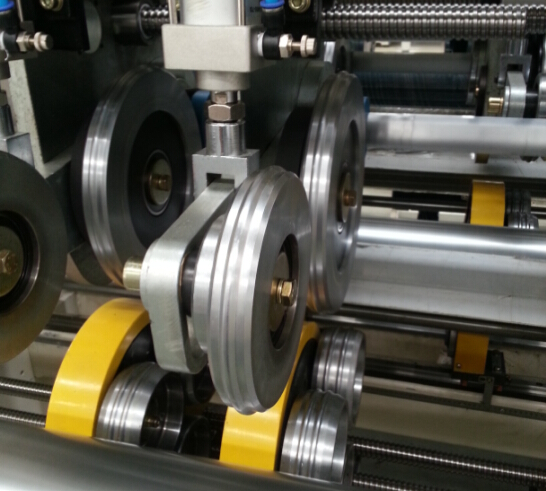

Thin tungsten alloy steel blades, sharp and long serving time, more than 8 million meters.

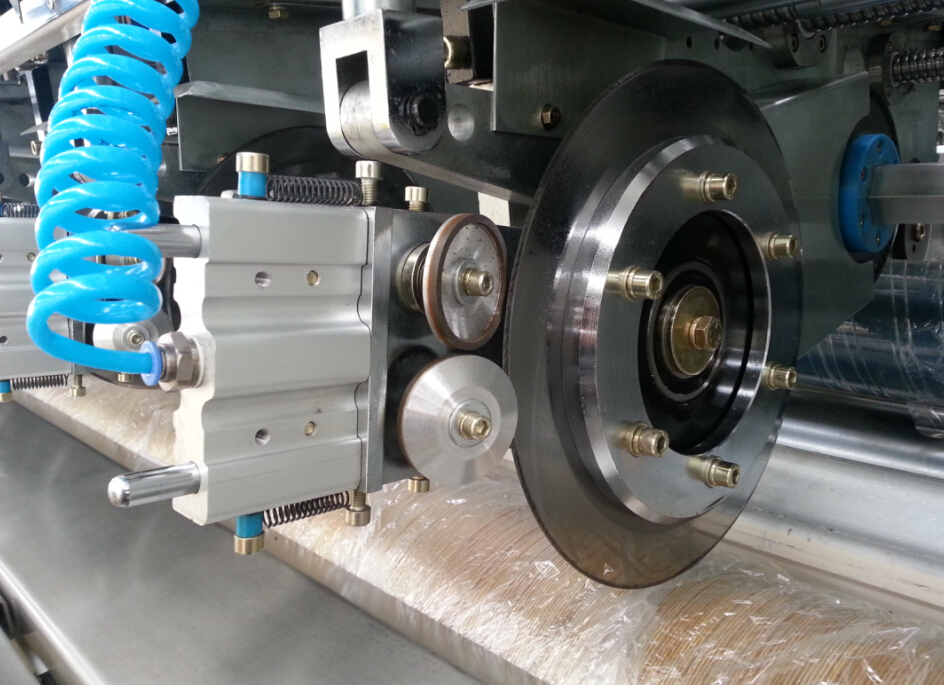

Patent passive type grinder, high and handy structure, easy maintenance.

Computer controlled auto grinding or manual grinding, knifes can be grinded while cutting at the same time to improve the productivity.

Well seleted three types scorer: Convex on concava(single wall); Convex on concava(double wall) can convex on flat, which can be altered by electrical driven system.

Scoring line depeth is controlled by computer, with fine scoring results for easy board floding.

Imported synchronous belts for conveying device with higher precision, longer serving life and lower noise.

Papameters

| No. | 1 | 2 | 3 |

| Type | NCFY-SK-1800-5/8 | NCFY-SK-2200-6/10 | NCFY-SK-2500-7/12 |

| Max. slitting width | 1850mm | 2250mm | 2550mm |

| Min. slitting width | 135mm | 135mm | 135mm |

| Total power | 16.25kW | 20.25kW | 20.25kW |

| Dimension | 3680*1650*2340mm | 4080*1650*2340mm | 4380*1650*2340mm |